Octanol water partition coefficient

What on earth is an 'octanol water partition coefficient' and what possible relevance could it have to cooking?

Well to answer the second part first, it is very relevant, it can be enormously useful when considering flavour distribution in our food

It can be explained as follows: for the moment, instead of octanol (an alcohol with eight carbon atoms) think vegetable oil.

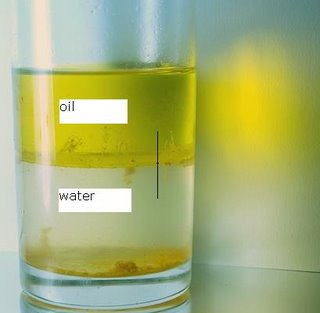

Take a glass bottle, say 200mm high and 50mm diameter (the size is actually irrelevant!) and add a little water to it, say 50mm depth. Now add the same volume of a vegetable oil. This oil will float on top of the water. Now add a teaspoon of turmeric powder, the yellow coloured powder used in Asian cooking, then cap and shake the bottle for a while. Let it settle, so that you end up with two layers of liquid, and a sediment of turmeric powder. Look at the two layers of liquid. What do you see?

When I did this experiment, I was quite surprised to see the oil layer was a golden yellow colour, and the water only lightly coloured, mostly from suspended turmeric powder.

What had happened was that the yellow colour in the turmeric, a substance called

curcumin, was dissolved out of the turmeric powder, and into the water and oil, except that most of it ended up in the oil, and very little in the water, which was evident from the depth of colour in each.

In fact, what had been performed was a very useful chemistry experiment, (although chemists use octanol instead of vegetable oil, as veg oil is quite a variable product, and octanol is a well characterized pure chemical). The curcumin is said to have

partitioned between the oil and the water, that is, quite simply, part of the curcumin is in the oil, and part in the water. This is quite usual with most organic chemicals.

If I had the equipment to measure the amount of curcumin in each liquid, I could calculate the amount in each, and give a value for the amount in the oil and the amount in the water. This would be very similar to a value using octanol and water, and the value is known as the '

octanol water partition coefficient'.

[stop press! I did measure the optical density of the two layers, after diluting the oil phase 1000 times with acetone, and filtering the water phase through a 0.2µm filter, at a wavelength of 420nm. My result was a veg oil/water partition coefficient (Kvow ?) of 2000 exactly, which agrees very well with the literature value for Kow of 1950 !]

How does this help the cook/chef?

With an understanding of the above and a little chemistry, it is possible to estimate (or even look up) values for the

octanol water partition coefficient. Most organic chemicals will have values between 100 and 1,000,000, this value is given the abbreviation Kow. The numbers (the coefficients) can be quite large, so it is common to use the log of the number, and it's usual to look up the log Kow of a substance.

So how is knowing the Kow or log Kow of a substance going to help with cooking?

Well, the larger the number (Kow), the more the substance will

partition into the oil. A substance with a Kow of say 100 will be 100 times more likely be concentrated in the oil than in the water, as long as the oil and water are in contact with each other, so the substance can move freely (partition) between the two liquids.

If we consider making a dish which has oil and water in it, we could estimate where the flavours would partition into, that is, estimate how the flavour would be distributed!or did you think the flavours were evenly distributed throughout the food? Nothing could be further from the truth.

In reality, as you might expect, the picture is more complicated, flavours not only partition between the oil and the water, but also between meat, bone, air, vegetables and possibly even the cooking vessel itself.

(See 'fugacity' below, for a fuller explanation)

So, the Kow is important in cooking, it can give us an idea of where flavours are likely to be. Remember the cooks saying, "the flavour is in the fat!" Now you know why! Most flavours are organic substances that have a relatively high Kow, so these substances will partition into the fat/oil, and also onto meat surfaces, especially if associated with fat. The Kow value also explains why it is better to fry spices in oil rather than add them to a dish when there is water present. The hot oil/fat will extract the flavours, the water will be much less efficient at doing so. It is common to fry whole spices in oil/fat when making Indian dishes, for example, such spices as cassia, cardamom, cloves and mace all contain flavour compounds with Kow's of 1,000 or more, so these flavours will end up in the oil and fatty meat, even though there may be a lot of water-based gravy. In many Indian dishes, it is suggested that the gravy be cooked until the oil just sepates from the water, at that stage an emulsion can form and the oil and water mix to some extent, thus distributing the flavours more evenly.

So to get the maximum flavour from your ingredients, think oil/fat! and think where your flavours might end up!!